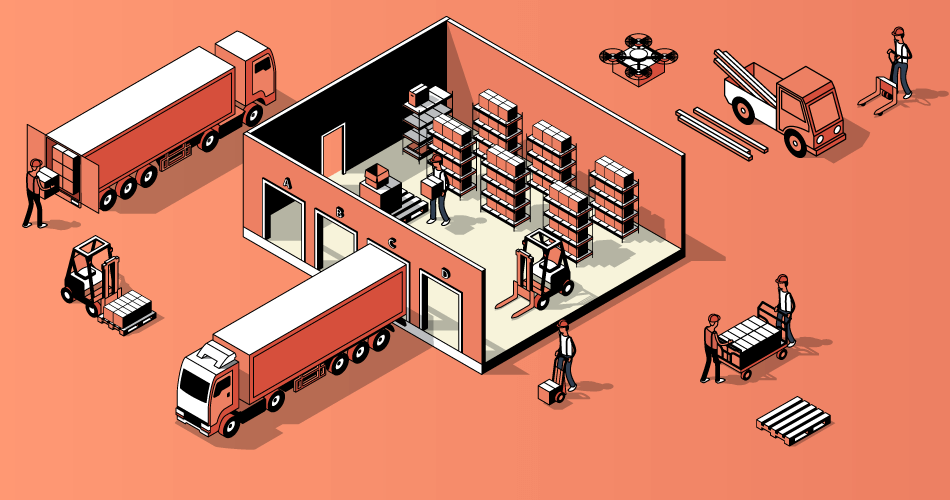

With the increasing global trade, both in terms of value and volume, a great number of shipments cross different borders and touch all the corners of the world every day. Logistics management teams of various countries make sure that the products and goods reach their customers safely and on time. Logistics management includes the management of everything in the supply chain from the raw material to its warehousing, the labor administration, the transportation of the final product to the information flow, all come under it.

Any discrepancy in the supply chain could result in severe consequences for logistics management. Therefore, with every new day, efforts are being made to make the supply chain better in terms of visibility, tracking, and transparency. For the past few years, the supply chain sector has evolved and expanded by a great deal. Technological innovation has solved a great number of problems and new ideas are also being given practical shape to add more efficiency in the supply chain in the future. Some of them have been discussed below:

1. Automation And Migration

As the distance between different countries has been reduced to quicker modes of traveling, migration has been increased. According to studies, migration has a positive impact on the supply chain. Their mass movement and mass shifting have also shifted economic possibilities creating challenges and opportunities for various organizations in different countries. Mechanical and intellectual automation has already taken control over some major aspects of the business world. Apparently, the future of the supply chain like all other things too will be led by technology.

Automation:

Machine automation has already helped a great deal in managing the strenuous tasks of the supply chain. Nowadays, computers are being equipped with technology that enables them to learn to analyze the data of charts, reports, etc. In a highly optimized manner and much quicker than any human. Robots and drones have already been assisting humans in many ways which are cost-effective leading to higher value addition. Automation has long term benefits for the supply chain leading to better coordination and collaboration. Some of them are:

Handling of Big Data and Tech-Driven Transparency:

Blockchain, having decentralized data structures can help in handling larger amounts of structured or unstructured data with better speed and efficiency at various steps of the supply chain. Therefore, adding transparency and accuracy to the whole process of the supply chain.

Unmanned Vehicles:

Driverless vehicles will become a trend in the supply chain in the near future increasing efficiency and speed.

Robotic Help:

Robotic help has already been used in the kitting, assembling an assortment of the products in the inventory. Their role is expected to increase.

Wearables:

Various gadgets like Google glass have the ability to count a huge number of products in a shorter time. They also assist in keeping a track of the truck drivers helping to avoid any delay.

RFID AND WMS:

This two software will soon become a norm and will be incorporated in the inventory management to add to its efficiency and speedy delivery.

Good Customer Relationship:

The automated warehouses and vehicles will make the handling of larger volumes of products much easier. Moreover, automated chatbots and voice bots will further help the organizations to improve their customer relationship.

Going Green

Automation leads to less fuel consumption leading to lesser carbon footprint. This is better for dealing with the current prevalent ecological crisis.

For making it further better, automation is also expected to be integrated in

- Data entering

- Data gathering

- Creation manipulation

- Invoice management

- Production and completion of forms

- Purchases

2. Cloud-Based System Trends in the Market

According to studies, the market for cloud-based products is developing at a greater pace. As it can streamline the operations with better security and transparency. The market of the cloud supply chain is expected to grow to 8.07 billion US $ by 2021. The usage of this technology is much easier and more advantageous when compared to other software of the same type. The use of this technology can result in high growth of E-commerce as it:

- Reduces potential failures

- Enhances supply chain continuity

- Works on a low initial investment

- Optimizes transport management

- Is safe to use

- Is easier to integrate with the already built systems

- Is affordable

- Is Highly efficient

3. Digitalize Distributed Inventory Systems

With technological advancement, people demand more speed and transparency in the whole supply chain process. At the same time, they also want the whole delivery process to be cheap. Moreover, the speed in the delivery process adds to its cost. With the increased competition in the logistics market, it is hard to keep up and stay ahead without incorporating technology. Modern ways of distribution can lead to a reduced cost as retailers can go for more warehouses for fast and cost-effective deliveries.

Distributed Inventory Flow Forecasting:

The efficiency of the supply chain cannot be compromised. So the warehouses should only have the status of being the points of the inventory flow. The distributed inventory flow forecasting ‘DIFF’ can help in predicting the flow of goods to maximize order fill rate and at the same time reducing the inventory levels leading to efficient handling of goods and shorter shipping times.

Digitization:

The online inventory management and e-commerce with the digital supply chain will enable the organizations to address the growing expectations of the customers with better and detailed orders and better transparency.

Integration of Digital Systems:

By providing a shared logistics infrastructure, the integration of digital software like WMS and RFID results in better handling of products and goods.

4. Virtual and 3D Digital Products

Virtual reality is emerging as a new trend and is influencing the supply chain. For example, the beverage industry by using imaging technology to know about the out of stock products. Many companies are using 3-D technology for on-demand production and personalization. The customers just need to order whatever they desire and the 3-D printers would produce it and the product would be delivered via drones or other automated transportation mediums.

Furthermore, one of the technologies of 3-D printing the ‘Digital twins’ is expected to revolutionize the supply chain models. They create a physical representation of not just physical products along with their process characteristics. 3-D printers are expected to follow the same path as the mobile phones having more

- Programmability

- Mobility

- Adaptability

The machine can make whatever the customer wants and just after a few hours they can have the product ready. The freight forwarders manage, coordinate and lead the whole supply chain. So, they are always looking for the latest technology to streamline the steps involved in the supply chain. As they are aware of all the complexities related to the transportation and logistics process. This technology is being integrated by the freight forwarders in the logistics process to make it efficient.

5. Role of Cloud Computing

Cloud computing is becoming a trend in the supply chain as it offers various benefits and the technology is making the supply chain more efficient and transparent. It provides an online platform to the retailers where the data can be shared with the customers. It has the following characteristics:

Agility

It has the ability to respond to ever-changing demand as it can deploy new services in a quicker and efficient manner.

Easier to use

The cloud is extremely easy to use. With a simple structure, it can provide quick access to accurate analytics from any part of the world.

Connectivity and Security

Cloud has the ability to retain the consistency and accessibility of information throughout the whole process. It provides real-time visibility having a good impact on efficiency and productivity. As the data of customers is critical and needs to be secured, the cloud is the best technology to do this job and keep the data safe.

Cost-Effective

It also offers several financial advantages providing insight to improve the business outcomes and, reduce the cost and improve the speed at the same time.

6. Wearable Technology

Wearable technology has already made its way into the supply chain with a voice automated picking system and scanners to scan the products. Nowadays, they are becoming extremely popular in the forward and reverse logistics process. The scanners like Google Glass helps the workers to scan and count a great number of products in just a matter of seconds. Along with that, the technology gives the retailers with the tools that are :

- Better

- Faster

- More effective in planning

This, in turn, allows the workers to put their focus on the high-level processes reducing chances of error and in building a better supply chain providing

- Speed and accuracy

- Improved safety

- Better quality

7.Augmentation and Automation

AI with its two characteristics of augmentation and automation are assisting humans in both personal and commercial tasks on a daily basis having full control over the output. With Augmentation, AI is helping with

- Data analysis

- Software solutions

- Virtual assistance

- Reduce errors

The automation of AI has already been discussed in the first paragraph with autonomous vehicles, automation in warehouses, etc. Robots had already been performing many jobs in the warehouses for kitting, assembling, assorting, etc. They are also completing main tasks in the manufacturing plants. Hence they are helping to

- Reducing Labour costs and more work

- Save time Time

- Save Cost

8. Next-Generation Robotics

The next-generation robotics is expected to take up the major roles of the assembly lines and other tasks. Robots are already playing a major role in the many of the production as well as in the packaging, assembling and in the assortment of the products. They are influencing major supply chain processes. They are assisting in self-driving vehicles and automated warehouse jobs.