The traditional manufacturing process demanded that raw materials be put through a chain of mechanical methods. Ultimately coming up with the desired object at the end of the various manufacturing stages.

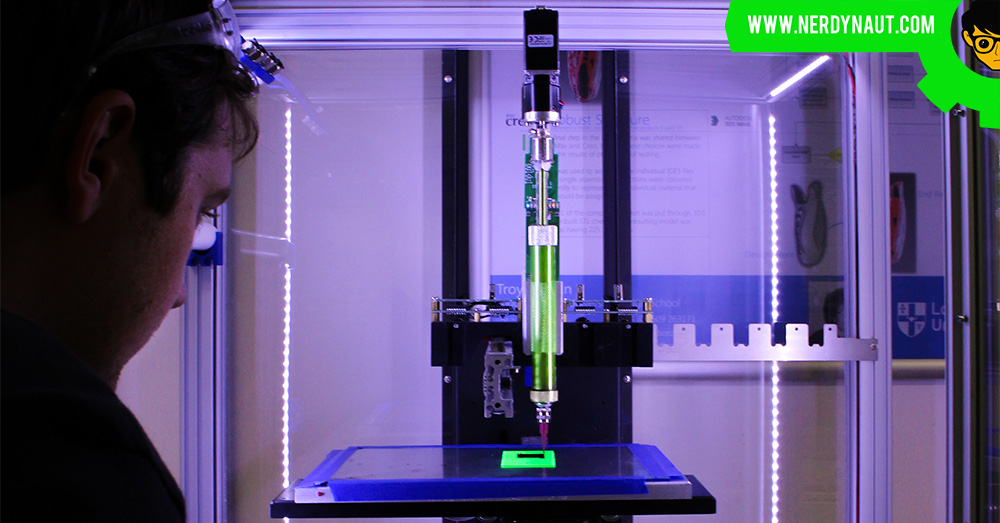

Over time, 3D printing, the cutting edge technology, also known as additive manufacturing, is progressively replacing the traditional manufacturing process. Thanks to the early inventions of Charles Hull who laid the foundations of the futuristic technology. With the 3-D printing, you automatically build a three-dimensional object through the ‘additive process.’

A few facts to unravel concerning 3D printing include:

1) There are five types of 3D printing technologies

Different 3D printers utilize either FDM (fused deposition modelling), SLA (stereolithography), SLS (selective laser sintering), SLM (selective laser melting), or binder jetting in coming up with object layers. All these processes run on different software such as CAD.

The first three are the most commonly used 3D technologies. In FDM, the different raw materials such as plastics are deposited into thermoplastic pools where they rapidly combine into a single 3D object.

In SLA, photoreactive curable resin materials are arranged layer by layer and later exposed to an ultraviolet laser for hardening. While In SLS and SLM technologies, raw materials in powder form are modelled into solid 3D structures.

2) 3D printing is leveraged on both small DIY projects and large-scale industrial manufacturing

There is a general misconception that 3D printing is limited to mass industrial production of various objects. Whereas the technology is significantly used in the automotive and medical fields, you could still venture into 3D printing at a small scale as an individual.

For instance, you could model a jewelry box, dices, coat hangers, six-pack carriers, and anything else in between. All you will need is an excellent 3D printer such as creality cr-10s or creality cr-10s Pro.

3) Any material can be 3D printed

As much as plastic is widely adopted for 3D printing of different objects, the technology supports a wide variety of materials ranging from wood, metal, to concrete. Any material with a substantially solid state can be 3D printed. Furthermore, combining two or more elements (though not currently popular) in the printing process enriches the filaments, adding quality to the end product.

On a different note, you do not have to be worried about an end 3D product with disappointing dull colors as different printers support a wide array of colors. Some as high as 50 different colors.

4) 3D printing is limited to the size of the 3D printer

The scope of the end product in a 3D printing process is limited to the size of the 3D printer. Therefore, large units can produce much larger objects whereas smaller units are restricted to small-sized objects. Nevertheless, precision is still best output by small-sized units compared to large ones.

5) 3D printing is the solution to cutting the costs of production

Unlike traditional manufacturing which needed several pieces of machinery and huge spaces to realize, 3D printing requires a few types of machinery and limited space. Furthermore, products can only be printed on demand, limiting wastage realized from dead stock.